Rubber properties

| Type | Advantages | Limitations |

|---|---|---|

| NBR |

|

|

| FPM (VITON) |

|

|

| ACM |

|

|

|

|

|

| SIL |

|

|

| EPDM |

|

|

| PTFE |

|

|

| HNBR |

|

|

| SBR |

|

|

Common used rubbers

| Type | Name | ASTM |

|---|---|---|

| NBR | Nitrile rubber | BF,BG,BK,CH |

| FPM (VITON/FKM) | Fluorocarbon rubber | HK |

| ACM | Polyacrylate rubber | DF,DH |

| SIL | Silicone rubber | FC,FE,GE |

| EPDM | Ethylene propylene rubber | BA,CA,DA |

| PTFE | Polyterafluoro ethylene | |

| PU | Urethane rubber | BG |

| AEM | Ethylene/Acrylic rubber (VAMAC) | EE,EF,EG |

| CR | Chloroprene rubber | BC,BE |

| HNBR | Hydrogenated NBR rubber | DH |

| SBR | Styrene Butadiene Rubber | AA |

Rubber specifications

| NBR | FPM | ACM | SIL | EPDM | PU | CR | SBR | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength | ● | ● | ▼ | ▼ | △ | ◎ | ● | △ | ||

| Elongation | ● | ▼ | ▼ | ◎ | ● | ◎ | ● | △ | ||

| Rebound Resistance | ● | △ | △ | △ | ● | ◎ | ◎ | △ | ||

| Tear Resistance | ● | △ | ▼ | ▼ | △ | ◎ | ● | △ | ||

| Abrasion-Resistance | ◎ | △ | △ | ▼ | ● | ◎ | ● | ● | ||

| Impact Strength Resistance | ● | △ | ▼ | ▼ | ● | ◎ | ◎ | ■ | ||

| Gas Impermeability Resistance | ● | ● | △ | ▼ | △ | ● | ● | ■ | ||

| Ozone Resistance | ● | ● | △ | ▼ | △ | ● | ● | ▼ | ||

| Weathering Resistance | △ | ◎ | ● | ◎ | ◎ | ● | ● | ▼ | ||

| Flame Resistance | ▼ | ◎ | ● | ◎ | ◎ | ● | ● | ● | ||

| Heat Resistance | △ | ◎ | ● | ◎ | ◎ | △ | ● | ● | ||

| Low Temperature Resistance | △ | ● | ▼ | ◎ | ● | ● | △ | ■ | ||

| Oil and Fuel Resistance | ● | ◎ | ● | △ | ▼ | ● | ■ | ▼ | ||

| Animal and Vegetable Oil Resistance | ◎ | ◎ | ◎ | ■ | ● | ● | ● | ▼ | ||

| Alcohol Resistance | ● | ● | ● | ● | ■ | ■ | ◎ | ● | ||

| Alkaline Resistance | ● | ■ | ▼ | ▼ | ● | ▼ | ◎ | ● | ||

| Acid Resistance | ● | ● | △ | △ | ● | ▼ | ● | ● | ||

| Aliphatic-solvent Resistance | ||||||||||

| - Aliphatic | ◎ | ◎ | ◎ | ▼ | ▼ | ● | ● | ◎ | ||

| - Aromatic | ■ | ◎ | △ | ▼ | ▼ | ▼ | △ | ■ | ||

| Oxygenated-Solvent Resistance | ▼ | ▼ | ▼ | △ | ◎ | ▼ | ▼ | ▼ | ||

| Water Resistance | ● | ● | ▼ | ● | ◎ | △ | ● | ● | ||

◎ Excellent

● Good

■ Suitable

△ Limited

▼ Poor

Rubber Specification Reference Table:

- Note for special type: ‘___-PL’ means oil seals are manufactured with TEFLON.

- Note: Numbers are composed of six digits. For example 4NK701 Rubber Code (4), NBR (N), Black (K), 70 SHA (7), Serial Number (01)

| MATERIAL | COLOR | HARDNESS | |||

|---|---|---|---|---|---|

| Code | >Explanation | Code | Explanation | Code | Explanation |

| N | NBR | W | White | A | 95 |

| F | FKM/VITON | K | Black | 9 | 90 |

| V | VAMAC | B | Blue | B | 85 |

| E | EPDM | R | Red | 8 | 80 |

| C | CR/NEOPRENE | T | Gray | C | 75 |

| S | SILICONE | G | Green | 7 | 70 |

| A | ACM | N | Brown | D | 65 |

| P | PU | O | Orange | 6 | 60 |

| L | FLS (LEATHER) | P | Purple | E | 55 |

| H | HNBR | C | Transparent | 5 | 50 |

| X | XNBR | Y | Yellow | F | 45 |

| R | NR | Note: Above colors are based on TCS standard, for other special colors, please take PANTONE for reference. | 4 | 40 | |

Material Temperature Range:

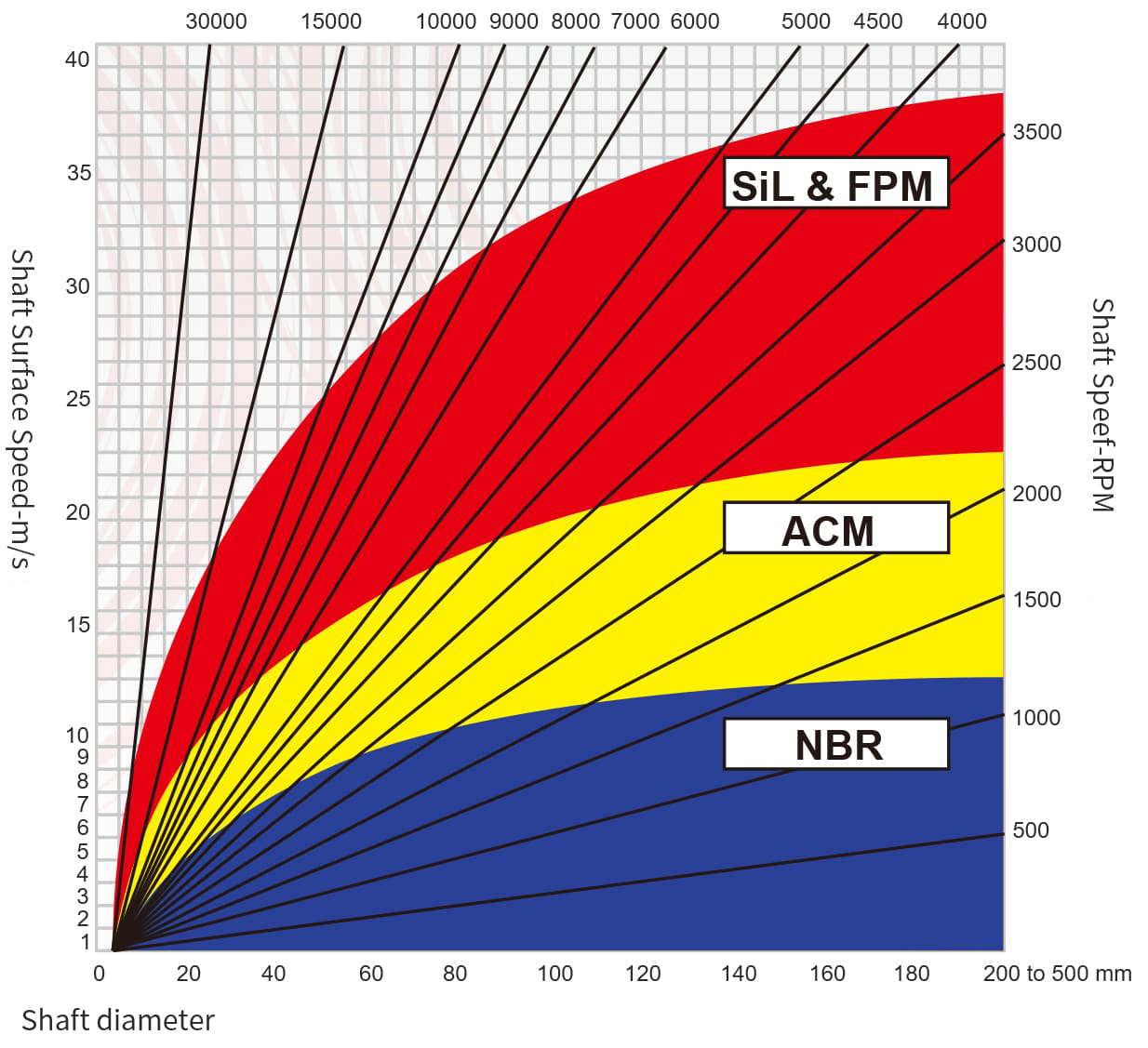

Shaft RPM, surface speed, and seal material application: